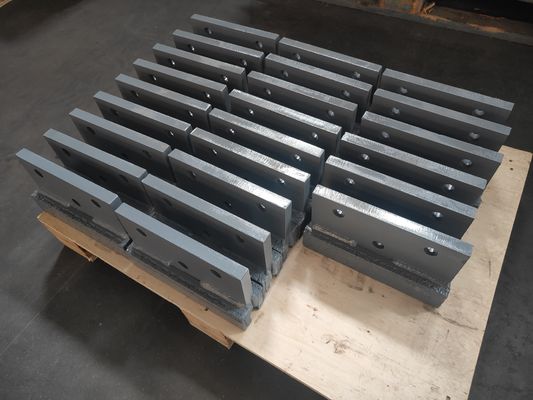

PM620 milling Parts 540-6797/5407967 Ejector plate Throwing shovel

1. Function and Purpose

Its core functions are to mount and secure the tool bits (cutting tools) and to eject milled material onto the conveyor system.

Tool Mounting: The ejector plate features precisely machined holes designed to secure carbide-tipped tool bits. It acts as the critical interface between the tool block and the drum body.

Material Ejection: This is the origin of the name "Throwing Shovel." During the milling process, the rotating ejector plates "scoop" up the milled material (asphalt, concrete, etc.) and use their specific shape and centrifugal force to efficiently throw the material rearward and upward, ensuring it lands accurately on the machine's conveyor belt. This process is vital for maintaining efficient material flow and preventing clogging around the drum.

2. Location

This ejector plate is bolted onto the milling drum of the Caterpillar PM620 cold planer. Multiple ejector plates are installed on a single drum in a specific helical pattern to ensure smooth milling operation and efficient material ejection.

3. Key Features

High-Strength Material: Manufactured from high-strength, abrasion-resistant alloy steel (such as AR400 or H450) and often heat-treated to withstand the tremendous impact, friction, and abrasion encountered during milling operations.

Precision Engineering: Its shape, angle, and position are meticulously designed and tested to optimize milling efficiency, reduce noise and vibration, and ensure optimal material trajectory.

Wear Part: As a direct participant in the milling process, it gradually wears down over time. Excessive wear can lead to enlarged tool holes (causing loose tools), reduced ejection efficiency, and potential damage to the tool blocks or drum itself. Therefore, regular inspection and replacement are necessary.

4. Part Number Information

540-6797 / 5407967: These are the genuine Caterpillar part numbers. These two numbers most likely refer to the same part, potentially representing variants in different systems or catalogs. 540-6797 is the standard hyphenated format, while 5407967 may be a simplified version. It is always best to confirm the correct number with your supplier before ordering.

Application: Primarily designed for the Caterpillar PM620 cold planer. It is always best practice to verify the part number compatibility with your machine's specific serial number.

5. Replacement and Maintenance

Replacing ejector plates is a standard part of drum overhaul and maintenance. Inspection or replacement should be considered when the following occurs:

Tools become loose or show abnormal wear patterns.

Material ejection becomes inefficient, leading to a buildup of material in the drum housing.

Visible signs of excessive wear, cracking, or damage are observed on the ejector plates themselves.

|

Product Name

|

rubber buffer

|

|

MOQ

|

1 piece

|

|

Applied to

|

road roller

|

|

Condition

|

100% New

|

|

Material

|

rubber

|

|

Colour

|

Black

|

|

Usage

|

anti-vibration

|

|

Quality

|

High

|

Q1.Are you a manufacture? A1:Yes,we have workshops and automatic production lines of rubber products, screed plates and electronic products. regarding to other items, we are OEM supplier. Q2.What is your supply capacity? A2.Annual output 650000 of track pads. Q3.Can you provide samples? A3.We can provide samples, but we need to pay the sample fee and freight. Q4.Do you have a minimum order? A4. Yes, It is up to different products. Normally MOQ 1pcs is acceptable. Q5. What is your delivery time ? A5. Around 7-10 days depend which products and quantities, please confirm with sales rep. Q6.Payment terms? A6. TT, LC at sight , DP are all acceptable / negotiable and case to case. Q7. CIF / FOB / EXW etc.. A7. FOB Shanghai or EXW with factory address at Taicang, Suzhou city, Jiangsu province. Pls send destination port for quote on CIF. Q8. Shipping A8: Air freight cargo,Train or sea shipment.

メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!  メッセージは20〜3,000文字にする必要があります。

メッセージは20〜3,000文字にする必要があります。 メールを確認してください!

メールを確認してください!